MSx Sim

Sensor Solutions to Optimize Sensor Hardware

Understanding Lidar data is hard.

What sensor is best for my applications?

How many sensors do I need?

Where do I mount sensors?

These questions make the barrier to entry for using Lidar sensors difficult. MechaSpin built MSx Sim to answer these questions and more. Using its innovative simulation engine, MechaSpin can simulate dozens for sensor solutions for any application to determine the optimal sensor hardware and layout to meet any customer's needs.

Benefits

- Select the right hardware the first time

- Understand how Lidar works for your project

- Accelerate development using synthetic data

- Easy, repeatable, testing of edge cases

Key Features

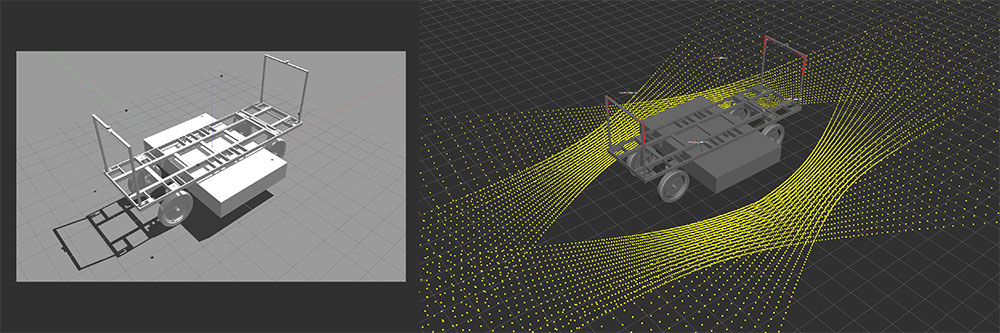

- Sensor Trade Study: MSx Sim enables us to rapidly simulate the output of multiple lidar sensors from different manufacturers to determine the optimal hardware for a use-case

- Synthetic Data Sets: MSx Sim generates prototypical output from one or more sensors for a use case. These data sets can represent static or dynamic scenes with either the sensor or the objects moving in the scene. Synthetic data allows us to quickly build solutions without the need for expensive prototype hardware installation and real-world testing

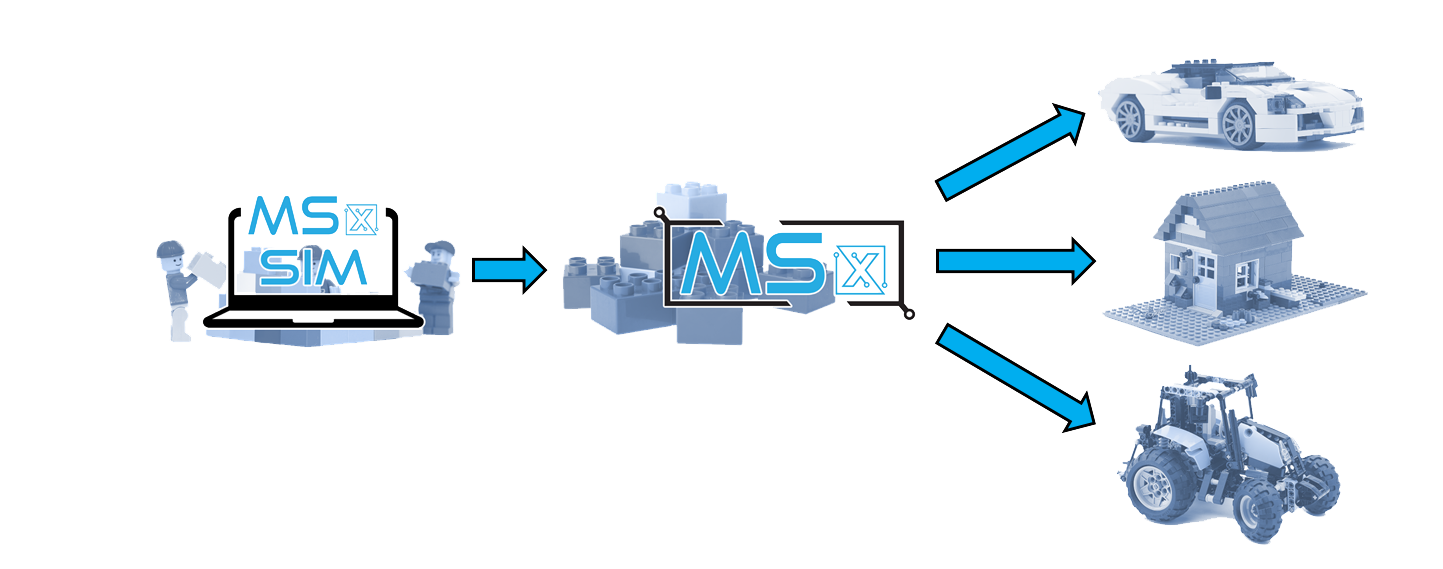

How it Works

MechaSpin integrates new types of low-cost 3D sensors (including lidar), and artificial intelligence into new products so our customers can bring breakthrough capabilities and competitive advantages to market by making their products safer and more collaborative with precision control.

Leveraging our MSx Sim and MSx Processing Engine solutions, we design and develop a custom solution to meet your needs. The MSx Sim provides instructions and design parameters for your solution. We then build your solution using our MSx Processing Engine and software capabilities.

We are a one-stop shop for custom 3D sensor solutions. We can design, build and implement a solution for you today!